Solid vs Engineered

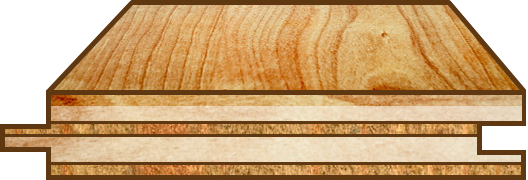

Traditionally, hardwood flooring came in thick planks of solid timber. Today, solid hardwood is still widely available, but many companies also offer engineered flooring—planks made with a thinner top layer of hardwood, bonded to other layers designed to prevent the floor from shifting during expansion and contraction cycles.

For basements and apartments with concrete subfloors, engineered flooring offers an installation advantage. Whereas solid wood is generally installed over one or two layers of plywood, which can raise the height of a floor and interfere with existing doors or marginally reduce ceiling height, engineered flooring can be glued directly to concrete, or over a soundproofing mat, and it’s also suitable for installation over radiant heat.

Solid Hardwood Floor

Engineered Hardwood Floor

Solid hardwood floors pros – Each board of solid hardwood flooring is made from a single piece of hardwood that’s about 3/4 of an inch thick. Because it’s so thick it can be sanded down and refinished for however long the flooring is in the house.

Engineered hardwood pros – Versatile and resilient flooring option that can be installed in most areas of your home. Made of genuine wood, this flooring gives your home an updated look and feel. Engineered hardwood is made of a core of hardwood or plywood with a layer of hardwood veneer affixed to the top surface. It’s more resistant to moisture and heat compared to solid hardwood.

Solid hardwood cons – Expands and contracts in reaction to changes in moisture and temperature, so solid wood floors are only recommended for rooms at ground level or above.

Engineered hardwood cons – Some engineered floors have top layers so thin that they can’t be sanded and refinished in the future. Higher-quality products feature a thicker layer where you’re getting as much usable wood as you would out of a solid board but with solid hardwood you can only use the part above the tongue and groove for refinishing.

Wood Grades

Grades range from a Clear Grade that is very uniform to a Rustic Grade grade that contains a beautiful array of characters. The photos below are examples of the 4 basic grades of White Oak as defined by the National Wood Floor Association.

Clear / Prime

Select & Better

#1 Common

Rustic / Character

- Clear / Prime: This is the best grade of hardwood flooring because there are few color variations, board lengths are not widely varied, and there are little to no visible knots or pinholes.

- Select and Better: This grade is slightly lower than the clear, still presenting uniform color and little to no knots and pinholes.

- #1 Common: This grade presents with more color variation, shorter board length with greater length variation, with an increased chance of visible knots and pinholes.

- Rustic / Character: Boards show natural character, with darker and lighter boards, shorter board length, with an increase in visible knots and pinholes.

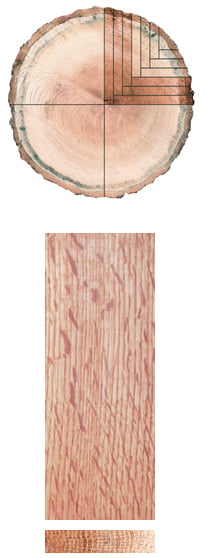

Wood Cuts

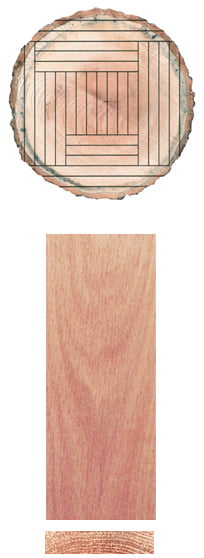

Plain Sawn

Rift Sawn

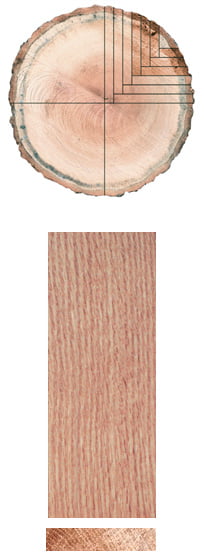

Quarter Sawn

Live Sawn

Plain Sawn:

The most common cut is plain sawn. The log is squared and sawed lengthwise in a series of parallel cuts. The annual growth rings appear as approximately straight lines on the board, joining at the end to form a “cathedral arch.” Because of this arch, plain sawn boards are often considered the most beautiful of the cuts. These boards are ideal for large visual areas like whole floors, tabletops, drawer fronts, sides of dressers or other similar projects. Plain sawn boards are the least expensive of the three cuts as they are the least labor-intensive to produce and leave the least waste.

Quarter Sawn:

Quarter sawn boards are created by first cutting a log into quarters and then making a series of parallel cuts perpendicular to the tree’s rings, cutting on the radius. The grain in quarter sawn wood is relatively consistent and the growth rings (grain) will be at a 60-90-degree angle in the profile of the flooring plank. This also makes quarter sawn boards less likely to bow, warp or twist than plain sawn. This makes it a good choice for floors being placed in high traffic areas.

Rift Sawn:

The third cut is rift sawn. In this cutting method, the log is still quartered, and then cut as you see on the right and in the video below. As the cuts get closer to the outside of the log the angle of the grain changes to 30-60 degrees and reducing the amount of ray fleks appearing in the wood. This makes it easy to match boards for a uniform appearance.

Live Sawn:

Is a very unique cut of wood which combines the grains found in plain sawn, quarter sawn, and rift sawn. This is an old method of sawing lumber used by olde world European Craftsman. To make live sawn, the sawyer slices the log directly through.